Gerber baby food location

Made in America? Not Exactly for These 5 Popular Products

Image source: The U.S. Army via Flickr.

Chances are that the phrase "Made in America" had a far different meaning for your parents. The "Made in America" label at one time exuded pride. It represented the toils of the American laborer that went into producing a product, and it gave the purchaser a sense of patriotism knowing they were purchasing a good manufactured within the United States.

However, today's economy is fully global, and from the smallest U.S. businesses to the most valuable corporations in the world, outsourcing manufacturing and services to foreign businesses has become fairly commonplace.

Why companies outsource

Why would U.S. companies risk losing the trust of American consumers to outsource part or all of their production? First, it has to do with costs. Popular outsourcing destinations such as China and India offer a substantially cheaper labor force, which can save a company money and allow it to keep the price of its goods and services relatively low.

Furthermore, outsourcing in China, Southeast Asia, or India opens up new markets for U.S. businesses. It can also improve supply chain management if parts are being purchased or sold in overseas markets. Finally, it allows overseas contractors to offer their perspectives, which domestic businesses may not otherwise have access to.

Nonetheless, some Americans take the "made in America" ideal seriously, and outsourcing can cost America jobs. While most U.S. companies have gotten away with outsourcing some or all of their business without too much backlash at home, producing products in overseas markets can still elicit a negative reaction from American consumers.

Made in America? Not exactly

With this in mind, here are five popular consumer products in America that you may not realize are actually produced (at least predominantly) in overseas markets.

Image source: Levi Strauss.

Levi's

Denim maker Levi Strauss is actually one of the most patriotic brands in America, according to the annual rankings from New York-based Brand Keys. The rags-to-riches story of its founder, as well as the durability of the brand, are hallmarks that have established the privately held business as an icon of America.

The rags-to-riches story of its founder, as well as the durability of the brand, are hallmarks that have established the privately held business as an icon of America.

However, truth be told, there are very few factories left in America that produce Levi's. As of September 2014, there were more than 500 factories around the globe producing accessories for Levi's, including just nine within the United States. Remember, this is a premium denim brand with a relatively high price point, so keeping manufacturing costs low is important to keeping its final prices from getting out of hand. Thus far it appears the move overseas hasn't hurt the appeal of the Levi's brand.

Image source: Flickr user Sean MacEntee.

iPhones & iPads

OK, so this one may not come as a huge surprise, but two of Apple's (AAPL 2.83%) extremely popular products -- its iPhone and iPad -- both come out of China (although the Philippines will soon be making iPhones, too). The obvious reason to manufacture these products in overseas markets is to keep costs down. Monthly labor costs in China are around 10%-20% of what a full-time worker in the U.S. would make at the federal minimum wage. Given Apple's penchant for introducing as many new gadgets as possible in its phones and tablets, keeping manufacturing costs down is imperative.

The obvious reason to manufacture these products in overseas markets is to keep costs down. Monthly labor costs in China are around 10%-20% of what a full-time worker in the U.S. would make at the federal minimum wage. Given Apple's penchant for introducing as many new gadgets as possible in its phones and tablets, keeping manufacturing costs down is imperative.

However, it's about more than just costs. China's greenhouse emissions laws are considerably more relaxed than those of the U.S., and as iFixIt.org pointed out in 2013, China is also home to a vast majority of rare-earth metals, which are used in the production of Apple's core mobile products. In this instance, Apple is making its supply chain more efficient by keeping production based in China, where rare-earth mines are located.

Of course, all design aspects of the iPhone and iPad come directly from Cupertino, California. There's no outsourcing of innovation on Apple's part.

Based on Apple's No. 1 brand value ranking worldwide, according to BrandZ, I don't believe its outsourcing is harming its reputation much.

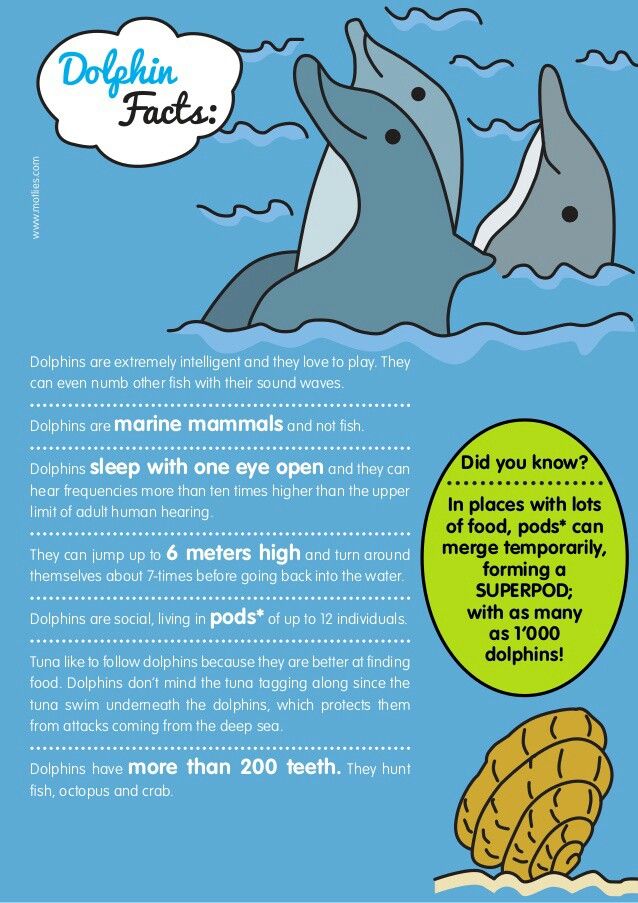

Image source: Gerber.

Gerber baby food

Most of us have seen Gerber commercials -- or may even have the Gerber baby's face emblazoned in our minds from walking down the aisles in the grocery store. Once an American company based in Michigan, Gerber is now owned by Swiss company Nestle (NSRGY 1.06%). Although it retains some American factories -- for its infant formulas, for example -- the majority of Gerber baby food is produced outside the confines of the United States.

Although the company isn't as forthcoming as Levi Strauss with its factory list, Nestle lists Poland, Venezuela, and Mexico as affiliated country websites that consumers can visit on its corporate page, implying that these are likely some of the manufacturing locations outside the United States. Like the others companies listed here, Gerber doesn't appear to be suffering from its ex-U.S. production: It claims U.S. baby food market share of 71% as of 2013.

Image source: Flickr user Laura Flores.

Major league baseballs

There may be no sport more American than baseball. Known as America's pastime, baseball began in the 19th century and continues today, with data from ESPN showing that approximately 73,760,000 people were in attendance in MLB ballparks in the 2015 season.

Here's the real kicker: The baseballs being used in MLB games from Rawlings aren't American-made -- and they haven't been for decades.

Rawlings, which is one of many components of Jarden (NYSE: JAH), produces rawhide baseballs in Costa Rica. Whereas global expansion is on the minds of Apple, Nestle, and even Levi's, Rawlings made the move specifically to keep its costs down and its profits up decades before outsourcing was even considered an issue in the United States. As of 2010, the typical worker hand-stitching baseballs in Costa Rica earned around $1.60 per hour, compared to the $7.25 federal minimum wage in the United States.

Image source: Barbie.

American Girl & Barbie

These are the toys that many children have loved for generations, but Mattel (MAT 6.32%)-owned Barbie dolls and American Girl dolls aren't made in America. Instead, as has been a mainstay in Mattel's production line for more than a decade, they are predominantly manufactured in China, along with many other Mattel toys.

Mattel's use of Chinese labor was a way of reducing costs and facilitating quick access to supply chain products that were also coming from China. In other words, this outsourcing was an attempt to make Mattel's supply chain as efficient as possible. Unfortunately for Mattel, this company actually has faced backlash for using outsourced labor.

In 2007, Mattel wound up recalling about 19 million toys, 18.2 million of which had small but powerful magnets that could be harmful to children if swallowed, along with about a half-million toys that were covered in potentially harmful lead paint. Mattel also wound up apologizing to China for enforcing weak safety standards that allowed dangerous materials to be put on toy-store shelves.

Mattel also wound up apologizing to China for enforcing weak safety standards that allowed dangerous materials to be put on toy-store shelves.

Not surprisingly, sales of Barbie, and even American Girl, have struggled in recent years. While outsourcing isn't the only issue here, Mattel's image was obviously not helped by these problems less than a decade ago.

Looking back at Asheville, NC’s Gerber baby food factory - AVLtoday

Photo courtesy of Buncombe County Special Collections.

Table of Contents

Quiz

When you think of baby food, what comes to mind? If you’re a native to the region, there’s a good chance you think of Gerber, which had a baby food factory here for 40 years located where the Gerber Village shopping center stands today in South Asheville. Let’s wander down memory lane, shall we?

Let’s wander down memory lane, shall we?

The Gerber company was founded in Freemont, Michigan in 1927 and made its way to Asheville in 1958. Construction on the 45-acre plant site began in 1958, and the nearly 300,000-square foot production area began operation Nov. 16, 1959. During its time in operation, it not only employed hundreds of workers — including some 700 people in its heyday — it acted as an important part of the community by sponsoring blood drives + art exhibits, as well as offering college scholarships to employees and their children. The Gerber plant was also a popular field trip destination.

Gerber Products Co. I Photo courtesy of Buncombe County Special Collections.

The plant was also a major supporter of area farmers. In fact, officials quoted in a Jan. 25, 1959 piece in the Asheville Citizen-Times said area produce + poultry farmers received over $1. 5 million annually from the company. Gerber was a major customer of Henderson County’s apple crops, and the company also purchased copious amounts of regionally produced sweet potatoes, peaches, pears, peas + more — enough to process 2.1 million jars of food a day.

5 million annually from the company. Gerber was a major customer of Henderson County’s apple crops, and the company also purchased copious amounts of regionally produced sweet potatoes, peaches, pears, peas + more — enough to process 2.1 million jars of food a day.

Area students tour the Gerber plant. I Photo courtesy of Buncombe County Special Collections.

A 1959 Citizen-Times article noted that area produce and poultry farmers received over $1.5 million annually from the company. Major crops included Henderson County apples, plus sweet potatoes, peaches, pears, peas + more — enough to process 2.1 million jars of food a day. Official + colloquial accounts note the Asheville plant’s efficient production schedule, including observations that it outperformed other plants. So employees were understandably confused when they got word in 1997 that the plant would shutter its doors in 1998.

Guests were given a commemorative spoon after touring the facility. I Photo courtesy of Vera Westall.

One of the few area plants that never had major layoffs, the news of closure was hard for workers, despite being given 10 months of notice and assistance from Gerber in the form of job training opportunities, including computer instruction. The company also opened a Career Center in April 1998 to help those laid off find new employment. Many workers lamented the difficulty + improbability of finding a comparable salary in the area (Gerber paid an hourly wage of $12-$15).

So why did Gerber decide to close its Asheville location? Company officials cited the lack of room for expansion, the declining birth rate, and a diminished demand for baby food. While the site was sold in 2011 and went on to become a thriving mixed-use development, locals still miss the factory and the sense of community it held for employees + customers alike — some even miss the smell of baby food in the air (especially banana).

Special thanks to the staff of Pack Memorial Library‘s Buncombe County Special Collections and everyone in the “You know you grew up in Asheville, North Carolina if....” Facebook group for their help.

Our history | Nestlé Baby&Me

More than 85 years ago none of the Gerber family could have imagined that with the light hand of a caring mother and wife Dorothy Gerber her husband's small cannery in the US state of Michigan would become famous all over the world. Today, Gerber ® baby food is known to parents all over the world.

1927

The history of the company began in the kitchen, where young mother Dorothy Gerber, wife of a cannery owner hand-mashed for their seven-month-old daughter Sally. The labor-intensive process took a lot of time and effort - this gave Dorothy an idea:

“If a factory can make mashed vegetables for

adults, then it will be able to make ready-made mashed potatoes for children”

After conducting the necessary research, consultation with nutritionists, doctors and economists in 1927 a trial batch of the product was produced.

1928

By the end of 1928, , after the new product was approved, five varieties of Gerber® baby puree were produced. every major grocery store anywhere in the US.

1930

Gradually Gerber® puree became known all over the world

Parents appreciated not only high palatability of ready-made food, but also a significant saving of one's own effort and time compared to the usual way of preparing baby food.

Two years earlier, the company held a competition for

The best illustration for advertising Gerber®

1931

in a figure sent by by the artist Dorothy Hope Smith , an unfinished portrait of a little girl - Anna Turner, the daughter of an author’s neighbor.

Advertising with this illustration was so successful that since 1931 the portrait of the girl's face becomes the official logo of the Gerber brand ® , registered as a trademark.

1950

Gerber® experts were among the first to offer a product of impeccable quality, that meets all the needs of young gourmets and is completely safe.

Tempered glass , which is used to make puree jars, makes it possible to apply heat treatment methods that destroy harmful microbes.

1963

The company's specialists have developed the first ever baby food cap with a special tab - an indicator of tightness.

When the lid is opened for the first time, a characteristic popping noise is heard, which helps parents to determine the freshness of the baby puree.

Since 1936, Dorothy Gerber began to personally answer

every letter that came to the company's address.

1968

And in 1968, Gerber® launched a single 24/7 telephone line, the Care Line, where parents could call and ask their questions to Gerber® experts at any time.

In the US, the line receives approximately 800,000 calls each year.

1998

Gerber ® manufactures approximately 500 products that can be purchased in more than 30 countries worldwide.

According to a 1998 US study, consumers trust the Gerber® brand more than any other brand.

2012

In Ukraine, the product range is represented by more than 30 items, among them are fruit, vegetable, meat and vegetable purees, fruit juices, meat purees, fruit purees in soft packaging, organic fruit purees. nine0004

Ukraine also has a “Care Line”:

specialists working on it respond to more than

50 requests from Ukrainian mothers every month.

HOW

GERBER Zucchini CHILDREN PUREE IS PRODUCEDGrocery Business

Denis Savoskin

World-famous baby food brand Gerber® has launched a new website where you can find comprehensive information about baby food purees. nine0164

nine0164

The main goal of the project is to provide parents with an opportunity to trace the entire path of mashed potatoes from the farm to the store shelf: where the crop is grown, how the product is produced, how its quality is ensured and monitored and under what conditions it is stored.

“One of the most important stages in a child's life is the introduction of complementary foods. It affects the further health and formation of taste preferences, which often persist for life. We know that parents choose the best for their children and take their baby's nutrition seriously. It is really extremely important for them to understand what parameters to choose products, what it consists of or where it is produced. For these purposes, the specialists of the Gerber® brand have launched a new website. Now moms and dads will be able to get comprehensive information about Gerber® puree – all the stages of its production and useful properties,” commented Sofia Bryantseva, Leading Nutritionist at Nestlé Russia.

nine0009

The complementary feeding phase is a “critical window” for developing food tolerance and preventing micronutrient deficiencies. Vegetable complementary foods are recommended to start with monocomponent purees, which are in the Gerber® baby food line, a well-known brand with more than 90 years of history.

For example, Gerber® zucchini puree is made from vegetables grown on farms in the Ebro Valley, on the Ribera del Douro and in Alicante (Spain). The fields are located very close to the processing workshops - no more than three hours pass between harvesting and fruit processing, which guarantees the maximum preservation of the useful properties of fresh zucchini. nine0009

By the way, marrow is a very difficult vegetable to use in the production of complementary foods. To produce a puree that meets Gerber®'s exacting standards, the nitrate levels and water content of the zucchini flesh must be carefully controlled. To do this, the company has developed a special strategy for their cultivation and preparation.