Can you reuse baby food pouches

Baby Food Pouches and Other Practical Ways to Store Baby Food

·

Written by Jo Charnock

·

Written by Jo Charnock

On this Page:

- Reusable BPA & BPS Free Baby Food Pouches

- Silicone Muffin Cups

- Freezer-Safe Jars

- Reusable Ice-Pop Pouches

So you got a bit carried away and made a whole big batch of homemade baby food. Too much to use in a couple of days. Can you store the extra baby food and for how long? Reusable baby food pouches are just one easy way to store your homemade baby food, but there are other practical ways to store baby food too.

The various different containers that are available to use don’t have to take up a huge amount of space or break your bank balance. In addition, you don’t need a whole new freezer dedicated solely to storing your baby food. Use the right containers and keep portions small and manageable.

Most importantly, experiment, have fun and find out what works for you.

Reusable BPA & BPS Free Baby Food Pouches

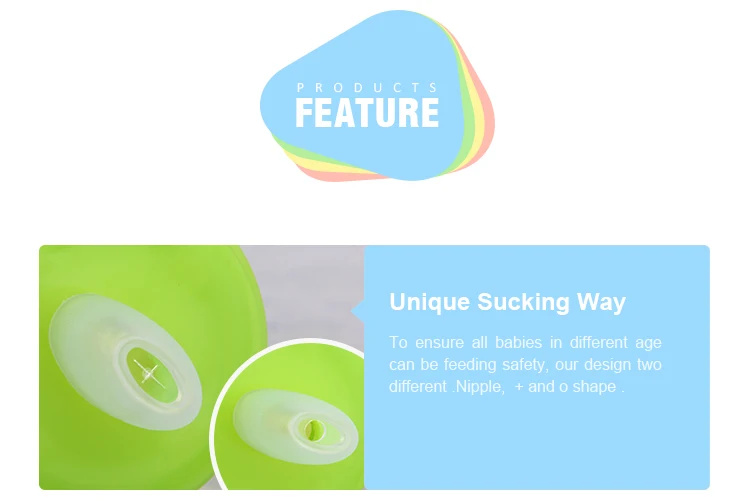

These are extremely easy to use and store baby food. You can use baby food pouches in the fridge or freezer, plus you can warm and serve homemade baby food straight from the pouch. Simply prepare your homemade baby food, fill up the baby food pouches and store in the fridge or freezer. Best of all, you can reuse your reusable baby food pouches time and time again!

Silicone Muffin Cups

Muffin Cups are strong and flexible and just the perfect size to store a single serving of baby food. Make your baby’s puree and pour it into these individual cups to freeze. For longer storage times pop the portions out and store them in the freezer in a tupperware container.

For longer storage times pop the portions out and store them in the freezer in a tupperware container.

Freezer-Safe Jars

You can use glass freezer safe jars to store baby food. However, not all glass jars are freezer safe as they can shatter or chip in extremely low temperatures. So make sure the glass jars you use are marked as freezer safe. Plus leave a space between the top of the food and the rim of the jar to allow for your baby food to expand when it freezes.

Cherub Baby has introduced a new range of gass and silicone baby food jars especially designed for freezing and storing your homemade baby food.

Reusable Ice-Pop Pouches

These reusable ice-pop pouches are quick and easy to use, just like baby food pouches. However, they are a great way to make healthy ice pop treats using fresh fruit purees. The Cherub Baby starter pack comes with a handy collapsible funnel to make pouring and filling your pouches easy!

Cookie

Sheet SplatsCookie sheet splats are a fun, fast and cost-effective way to store baby food. Simply cover a baking tray with baking or wax paper, drop individual spoonfuls of your homemade baby food onto the paper and then freeze. When the splats are frozen you can store them in freezer bags or a tupperware container to use at a later date.

Simply cover a baking tray with baking or wax paper, drop individual spoonfuls of your homemade baby food onto the paper and then freeze. When the splats are frozen you can store them in freezer bags or a tupperware container to use at a later date.

IMPORTANT TIPS TO REMEMBER

Whichever method you choose to store your baby food, remember it is essential to do it correctly and for the correct amount of time. Storing baby food at the wrong temperature or for too long can cause bacteria to grow which is harmful to your baby. Homemade baby food can be kept in sealed containers in a refrigerator for up to 2 days. If you freeze your homemade baby food it can last for 3 months. Never leave baby food at room temperature for longer than 2 hours.

Plus don’t forget to label and date the containers. There’s nothing more frustrating than trying to figure out what that baby puree is, or when you made and stored it. Labelling and dating your baby food will also help with food rotation. Always use the older food first, but again remember if it’s frozen, use it before it is three months old.

Labelling and dating your baby food will also help with food rotation. Always use the older food first, but again remember if it’s frozen, use it before it is three months old.

For further information please read the guide ‘How to Store Baby Food‘ from Wikihow.

Hopefully, this has helped to shed some light on how to store your baby food in a easy and safe way.

Read more about our Reusable BPA and BPS Free Baby Food Pouches and find out how easy it is to store and feed your little one. You can also find out more about our Freeze n’ Squeeze Pouches here. 🙂

Need some more info about introducing solids to bub? Check out our guide here!

Any questions or comments? sound off below 🙂

Find out more about all the features of our Reusable Baby Food Pouches!

Tagged in

- Using baby food pouches

Continue reading

Newborn Baby Essentials For Feeding

How To Warm A Baby Bottle Safely

The Baby Thermometer, A Basic Tool In Your Baby 1st Aid Kit

Do-It-Yourself Reusable Baby Food Pouches

Home » Guest Post Submissions » Do-It-Yourself Reusable Baby Food Pouches

Published: by Crystal Paine on | This post may contain affiliate links. Read my disclosure policy here.

Read my disclosure policy here.

Guest post from Elise

Baby food pouches came out a few years ago when my now four year old was a toddler. They were immediately a huge hit with many of my mommy friends. I have always made my own baby food, so I never bothered to purchase any of the store-bought pouches.

After the birth of my third son earlier this year, I was still committed to making my own baby food. However, a few weeks ago I was walking through the baby section and found myself in the baby food aisle. The colorful, transportable, spoonless, feed-as-you go food pouches were calling my name and persuaded me into buying two of them for a busy-on-the-go week… just to see what all the fuss was about.

The price was less than alluring at $1 a pouch (sale price), but I figured this was just a one-time purchase, so it wasn’t a big deal. The problem was, after using one of the pouches, I was hooked! I was amazed at how easy it was to feed him while we were out and about — so much less mess, and he seemed to like it, too!

So, I started researching refillable pouches online and was dismayed with how expensive they were. I wasn’t willing to invest that much, especially since this was our last child and I would only be needing them for a few months and would probably only use one or two pouches a week.

I wasn’t willing to invest that much, especially since this was our last child and I would only be needing them for a few months and would probably only use one or two pouches a week.

I was expressing my desire to do some sort of inexpensive, re-fillable pouches for all of our upcoming holiday travels to my husband; and he all the sudden chimed in, “Can you use the spout from the pouch you just used and put them in one of your icing bags?” Genius! Have I mentioned how glad I am that I married an engineer?

So, that is what I did. I took my two empty pouches, cut out the spouts, removed the foil as much as I could, and ran the spout and lid through the dishwasher. Then I dug out my cake decorating supplies and found my plastic, disposable piping bags and went to work. If you decorate any cakes the assembly will be pretty easy for you!

Amazingly enough, the lid will screw on over the plastic and still lock into place. I will not guarantee that these homemade pouches are completely leak proof. But throwing the pouch into a plastic baggie (that I re-wash later) is something that I am used to doing whenever I packed up my re-usable plastic containers, anyways.

But throwing the pouch into a plastic baggie (that I re-wash later) is something that I am used to doing whenever I packed up my re-usable plastic containers, anyways.

And, best of all, the piping bags that I buy are quality enough that after I feed my baby I re-wash the tip and bag for another use! Thus far, I am on my third use with one bag and it still works like a charm! (Quick tip: turn the bag inside out to pull out the spout!)

Approximate Total Cost:

12 Disposable Piping Bags = $3.99

2 Pre-filled Food Pouches = $2.00

TOTAL = $5.99 for 14 pouches (plus the 12 piping bags can be reused)

Not bad if you ask me!

Picture Instructions:

Carefully cut out the spout remove as much foil as you can. Wash thoroughly by hand or in the dishwasher.

Push the spout as far down into the disposable piping bag and snip the end with scissors. Reach in again and push the spout down as far as you can again to create a tight seal.![]()

Twist on the lid and lock it into place.

Carefully fill the bag with your home made baby food puree. (Consider filling it with applesauce or yogurt for your toddlers for when you are on the go). I recommend using a tall cup to hold the bag in place so you can be careful not to get too much on the sides of the top of the bag.

Twist off the excess bag and secure in place (I used a twist tie, but you could probably use a rubber band or even just tie it off.)

Feed your ridiculously cute baby!

Or let ridiculously cute baby feed themselves!

Elise Haroldson has enjoyed eight years of oneness with her dear husband Steve (who really deserves the credit for this amazing idea!). They have been blessed with three active little boys, ages 6, 4 and 10 months and love living on a 15 acre homestead in IL. Elise strives to maintain an orderly, budget conscious, fun and Christ-centered home, all while dabbling in the fine arts of gardening, baking, sewing, and photography.

She currently enjoys writing a quarterly “Cutting Corners” article for her church’s women’s newsletter.

More Posts Like This

Guest Post Submissions LITE Feed (non-deal) PostsReader Interactions

Money Saving Mom® Comment Policy

We love comments from readers, so chime in with your thoughts below! We do our best to keep this blog upbeat and encouraging, so please keep your comments cordial and kind. Read more information on our comment policy.

Flexible Packaging and Disposal Issues

Flexible Packaging and Disposal Issues

In three articles, we will provide you with a comprehensive coverage of the flexible packaging market with respect to recycling. To date, nowhere in the world there is a reliable system or technology for the recycling of used multilayer packaging containers. In this article, we will provide an overview of the current situation in the flexible packaging market and the problems that arise when processing packaging in this format. In the second article, we will talk about a recently appeared effective way to recycle packaging waste. And in the third final article, we will describe the module for the recycling collection of used packaging bags.

In the second article, we will talk about a recently appeared effective way to recycle packaging waste. And in the third final article, we will describe the module for the recycling collection of used packaging bags.

Flexible Packaging

The ever-changing lifestyle and resulting consumer reliance on pre-processed, pre-packaged and pre-cooked food is having a significant impact on the growth of flexible packaging bag sales. Rigid packaging in all its formats (cans, bottles, plastic containers, glass) is noticeably inferior to flexible and durable bags. Convenient format, light weight, excellent barrier properties, efficient use of resources and high quality printability are all benefits of flexible packaging.

Flexible packaging is the second most used packaging format in almost every part of the world. The food and beverage market is the largest consumer of flexible packaging, although pharmaceuticals are leading the way in terms of growth in the use of this packaging material. Today we see flexible packaging in almost every sector of consumer products. Doypacks are even used for packaging paints and motor oil.

Today we see flexible packaging in almost every sector of consumer products. Doypacks are even used for packaging paints and motor oil.

Highlighting the importance of using the flexible packaging format, companies such as Dow Chemical, who view packaging as a whole as a significant factor in reducing food waste, argue that flexible packaging is the defining moment in any strategy to reduce food waste.

Flexible Packaging Applications

Flexible packaging is widely used in place of rigid and semi-rigid packaging due to its versatile characteristics such as low weight, high strength, attractive appearance, cost effectiveness and ease of shaping. Flexible packaging is usually obtained by lamination and co-extrusion. The basic raw materials in the flexible packaging production process are polyesters, polyethylene film, metallized film, biaxially oriented polypropylene film, paper, adhesive adhesive, etc.

Made from polyethylene and polyethylene terephthalate, single-layer soft bags are easily and completely recycled. However, today's reality is that consumer goods companies have to use flexible multi-layer packaging to provide the contents of the package with sufficient protection from light, oxygen, air and any other harmful factors, as well as guarantee a shelf life that would suit consumers, retailers and suppliers.

However, today's reality is that consumer goods companies have to use flexible multi-layer packaging to provide the contents of the package with sufficient protection from light, oxygen, air and any other harmful factors, as well as guarantee a shelf life that would suit consumers, retailers and suppliers.

Today's market demands that foodstuffs have a shelf life of at least one year. And this leads to the need to use as packaging, the so-called multilayer "barrier materials" with high protective characteristics. Such multilayer food packaging structures are usually made of a layer of aluminum foil placed between several layers of a polymer film, and interconnected by lamination or adhesive.

Multilayer composite packaging

It would seem counter-intuitive, but adding layers to the complex structure of flexible packaging can improve the economic and functional performance of this type of packaging.

Whereas three- and five-layer packaging material designs were hugely popular recently, more and more converters are now moving towards the production of seven- and nine-layer co-extrusion film, which offers greater possibilities in terms of functionality, thickness and material cost without excessive complexity its structures. One of the technologies suggests using inexpensive grades of polymers as a bulk filler. Another technique involves dividing the barrier layer into two thin sublayers, one of which will play the role of a "reserve" in case of damage to the other. This technique also involves the impregnation of one material with another, which will further reduce the percentage of permeability. At present, the technology of separating barrier materials into several layers is being tested. Experimental data show a more than linear improvement in the protective properties of such packaging material.

One of the technologies suggests using inexpensive grades of polymers as a bulk filler. Another technique involves dividing the barrier layer into two thin sublayers, one of which will play the role of a "reserve" in case of damage to the other. This technique also involves the impregnation of one material with another, which will further reduce the percentage of permeability. At present, the technology of separating barrier materials into several layers is being tested. Experimental data show a more than linear improvement in the protective properties of such packaging material.

Most types of multi-layer packaging are not recyclable, and therefore are not taken from the general municipal waste stream and end up in a landfill for further disposal along with other municipal solid waste. Metal-plastic and paper-metal-plastic packaging is almost impossible to recycle due to the presence of various raw materials in their composition.

When we talk about recycling, we mean the recovery of several components of multilayer packaging, which can later be converted into recycled materials, and then, in combination with virgin polymers, are involved in the manufacture of new high-grade products. This process is often, although not quite correctly, referred to as "zero waste recycling".

This process is often, although not quite correctly, referred to as "zero waste recycling".

Due to the huge number of variations of polymer composite structures that are used in the production of flexible packaging, the recycling process is (practically) not feasible, as it is too complicated and too risky in terms of investment.

Note 1: In principle, the main difficulty is not the technology of flexible packaging processing itself, but the material selection process. That is, each individual flexible packaging component (i.e., layer) must be analyzed and categorized, and then separated and individually processed. Only this approach will ensure the maximum recovery of each component and make it suitable for further use.

Note 2: No professional packaging recycler will recycle used packaging because about 80% of flexible packaging containers are contaminated with food residue. And, therefore, doypacks are completely unsuitable for use in existing recycling systems, as they contaminate the final recycled material. This contamination makes the resulting material unsuitable for further use in the production of high-grade products.

This contamination makes the resulting material unsuitable for further use in the production of high-grade products.

Note 3: Even Nestlé notes that there are still no production plants in the world capable of processing flexible multilayer packaging. However, both Nestle and Kraft are co-funding a research project in the UK to develop a technology to extract aluminum from flexible laminates. Please note that the emphasis here is on aluminum. In a new developed research project, the polymer component of the flexible packaging is evaporated in a chamber in the absence of oxygen and used as an energy source. This process is contrary to the definition of the term "waste recycling" or "recycling waste". The use of packaging material as an energy source has nothing to do with the process of renewal. It's more of an end-of-life process where you simply destroy a valuable material resource in order to generate a few joules of energy mislabeled as renewable. Is it possible to call the process of burning plastic components and using energy renewable? After all, in the end you are left empty-handed. In other words, it's just a waste of valuable material.

Is it possible to call the process of burning plastic components and using energy renewable? After all, in the end you are left empty-handed. In other words, it's just a waste of valuable material.

Recycling and FMCG

If you decide to follow the development of the packaging recycling sector, you will notice that professional recyclers only work with packaging formats that are properly standardized. and PET), cans and cans for drinks (aluminum or steel), cartons and some types of plastic bags (PE or PET) are recycled without any problems, since the materials used in these types of packaging are easily separated. And recycling such waste can create a high-quality and expensive material that can be reused in the same area where it was created.

When it comes to flexible packaging, the light and food industries in particular are doing their best to maximize its usefulness and performance by creating complex structures that do not allow reuse of the container. Adhesives, composite materials, and coatings create complications that make it extremely difficult to classify, separate, and process flexible materials.

Adhesives, composite materials, and coatings create complications that make it extremely difficult to classify, separate, and process flexible materials.

As the second largest packaging format in the US, flexible packaging and the issue of recycling is an important issue in any discussion of sustainable packaging, including recycling. Consumer interest in addressing issues of sustainable packaging is constantly growing. Demand for flexible packaging is increasing as it is much lighter in weight than many other types of rigid packaging such as metal, PET and glass containers. By using lightweight packaging such as doypacks, companies can significantly reduce the amount of fuel used and also reduce the amount of greenhouse gases emitted into the atmosphere during transportation.

With all of this in mind, companies are calling packaging "recyclable" and "sustainable", stating that its main benefit is to reduce the amount of waste and resources used to produce it. According to statistics, 77% of plastic water bottles (22 billion) end up in US landfills every year. The companies claim that flexible packaging is significantly better, because due to its shape, it will take up 96% less space when landfilled compared to traditional PET bottles.

According to statistics, 77% of plastic water bottles (22 billion) end up in US landfills every year. The companies claim that flexible packaging is significantly better, because due to its shape, it will take up 96% less space when landfilled compared to traditional PET bottles.

But whatever they say, companies still face the challenges of recycling flexible packaging. Plastic PET bottles, their main point of comparison, can be and are recycled. But flexible packaging materials are not. And something needs to be done about it. Especially since the Extended Producer Responsibility (EPR) Act is about to come into effect.

In Europe, it was adopted 20 years ago as the ideal solution to landfill problems. Today, laws like the EPR are already in place in more than 30 countries. EPR programs bring costs and responsibilities into the marketplace. The law ensures that all participants in the life cycle of a product share responsibility for the impact of the product throughout its life cycle.

The Extended Producer Responsibility Act will become an inevitable reality for the US, China, Russia and other countries in five to ten years at the most. In addition to usability, waste quality control is one of the most important parameters for the future of packaging.

Market suppliers of flexible packaging

The largest supplier of doypack juices is Kraft Food and its Capri Sun brand. The company produces more than six billion flexible bags annually. The packaging is non-recyclable and the manufacturer does not label it as such. Kraft Food is trying to return some of its used packaging for recycling, but this is only a tiny fraction of the total volume of bags produced.

Sprout Organic Baby Food's Resealable Multilayer (PET/Foil/OPA/PP) Retort Bag won the Gold Award for Greenness and Sustainability. And yet, despite a number of user benefits and conveniences, such packaging is not recyclable.

It would seem that Sprout Organic has found a solution to the problem of flexible packaging recycling. Since multilayer laminated bags cannot be recycled, the company decided to prevent them from ending up in landfills. Working with TerraCycle ( www.terracycle.net ), Sprout Organic collects used bags and turns them into other consumer products such as shopping bags. The results of such an event are not yet known, but in general it can be said that it is unlikely that people actively supported this initiative and rushed to pack and send empty packaging bags to the company. Such a recycling method is very limited in terms of the volume of processed material. Moreover, the scope of work performed by the company also has limitations. TerraCycle, for example, only accepts packaging from Sprout Organic with layer designs it is familiar with.

Since multilayer laminated bags cannot be recycled, the company decided to prevent them from ending up in landfills. Working with TerraCycle ( www.terracycle.net ), Sprout Organic collects used bags and turns them into other consumer products such as shopping bags. The results of such an event are not yet known, but in general it can be said that it is unlikely that people actively supported this initiative and rushed to pack and send empty packaging bags to the company. Such a recycling method is very limited in terms of the volume of processed material. Moreover, the scope of work performed by the company also has limitations. TerraCycle, for example, only accepts packaging from Sprout Organic with layer designs it is familiar with.

In the context of this article, the statement made by Ron Romanik in his "Eleven Trends in the Formation of Flexible Packaging" published by Packworld seems idiotic. Quote: “ Energy recycling of waste is becoming an increasingly viable end-of-life step for flexible packaging materials. .., increasing the likelihood that US companies will support efforts to turn waste into electricity, syngas, fuels, and reusable materials. And this, in turn, can take to the next level of tasks, such as the implementation of corporate social responsibility programs ".

.., increasing the likelihood that US companies will support efforts to turn waste into electricity, syngas, fuels, and reusable materials. And this, in turn, can take to the next level of tasks, such as the implementation of corporate social responsibility programs ".

Interesting statement, isn't it? And since when has the burning of valuable non-recyclable materials been considered a requirement of social responsibility, whether corporate or not. This is not an example of social responsibility, but rather a shameful activity.

Fortunately, "responsible" consumer goods manufacturers are looking hard for a solution to the proper recycling of packaging materials, but so far to no avail.

The next article will look at recycling technologies and present possible solutions to this problem.

... to be continued

Freezing Homemade Baby Food Encyclopedia Baby Food

Viktoria Levchuk©

There are some important guidelines for freezing baby food that need to be followed, they are outlined on this page and there is even a diagram foods that can be frozen. We will show you how to freeze freshly made puree and store it. It will be interesting to read.

We will show you how to freeze freshly made puree and store it. It will be interesting to read.

Good to know!

- Frozen baby food leftovers - what to do with them, we will find out in the article.

- Heading Frozen food - all about baby food cubes.

- New thinking on allergens

Easy to use sitemap Encyclopedia Baby Food with a list of all articles and recipes.

How long do you keep baby food in the refrigerator or freezer?

Contents:

- Freezer: 4-6 months (ideally used within 1 month or 3 months)

- Refrigerator (fruit/vegetables): 24 hours

- Refrigerator (meat, poultry, fish eggs): 24 hours

For For optimum quality and nutrient retention, store Frozen Baby Food Cubes in the freezer for no more than 1-3 months.

Frozen baby food is safe to use if kept in the freezer for about 3-6 months without thawing again. However, it is more reasonable to use them in the region of 1 month to 3 months inclusive. Due to the amount of water crystals that accumulate in baby puree, and the fact that nutrients and important substances can be leached/evaporated when thawed due to these same water crystals, it is wiser to use your frozen baby food whenever possible. - no more than 3 months of storage. However, it is best to use within the first month after freezing, we advise.

However, it is more reasonable to use them in the region of 1 month to 3 months inclusive. Due to the amount of water crystals that accumulate in baby puree, and the fact that nutrients and important substances can be leached/evaporated when thawed due to these same water crystals, it is wiser to use your frozen baby food whenever possible. - no more than 3 months of storage. However, it is best to use within the first month after freezing, we advise.

Most sources advise storing fruit and vegetables for 8 to 12 months in the freezer. This is mostly true of whole foods that are congealed in their natural state. This is also provided that the refrigerator compartment remains at a constant temperature below zero. Deep-freezing is best if you want to keep frozen food for a long time. However, it should be remembered that the instructions and recommendations for freezing food for long-term storage do not imply that the fruit or vegetable has been boiled and mashed.

How long can baby puree be kept in the refrigerator?

In the refrigerator, it is not recommended to store fresh pureed homemade baby food for more than 24 hours. This limitation ensures that the growth of pathogens in the puree is kept to a minimum and that the food does not take on the “refrigerator flavor”. This "rule" applies to vegetables, fruits, meats, etc.

This limitation ensures that the growth of pathogens in the puree is kept to a minimum and that the food does not take on the “refrigerator flavor”. This "rule" applies to vegetables, fruits, meats, etc.

If you do not plan to freeze homemade baby food, then baby food for the baby is prepared every day if he is too small until 8-9months, or every other day, older than the specified age.

Why freeze baby food?

Save parent time, reduce food waste and ensure food safety.

For example, one potato was baked in the oven, and then half was mashed and the other half was frozen.

Frozen vegetables or fruits are safe in baby food

Fruits and vegetables can be frozen. Using frozen fruits and vegetables is the second best option after eating fresh. The quick freezing process (food is frozen at a very low temperature and very quickly) actually preserves the nutrients optimally. Cooking destroys more important nutrients than freezing food. Contrary to myth, freezing food (particularly fruits and vegetables) does not destroy 100% of minerals and vitamins. The freezing process, subject to storage conditions at a constant temperature of zero degrees, does not contribute to the complete loss of nutrients and important substances - if this is the case, then most of the population is malnourished, since in winter we eat a huge amount of frozen foods.

Contrary to myth, freezing food (particularly fruits and vegetables) does not destroy 100% of minerals and vitamins. The freezing process, subject to storage conditions at a constant temperature of zero degrees, does not contribute to the complete loss of nutrients and important substances - if this is the case, then most of the population is malnourished, since in winter we eat a huge amount of frozen foods.

Frozen vegetables not cooked at the time of packaging must be cooked before eating. Please remember to read the labels of frozen bags, as some brands of frozen vegetables may be pre-cooked.

One of the most frequently asked questions is "Can I use frozen fruits or vegetables for baby food and then freeze the puree?". Since there are no studies that show that repeated freezing is negative and / or can negatively affect health. The problem is that it is necessary to cook food from products that have been frozen once. But the reality is that a frozen product, going through all the stages from a fresh look to a frozen product in a refrigerator in a store, can survive several defrosting and freezing, as it was written earlier, it is through water crystals that nutrients leave. Therefore, purchased frozen vegetables and fruits must be carefully selected, and we would not recommend preparing baby food from them for subsequent freezing of baby puree. It is clear that sometimes parents have no choice and have to start complementary foods with purchased frozen food, so we carefully choose the packaging and the manufacturer, without holes, without pieces of ice.

Therefore, purchased frozen vegetables and fruits must be carefully selected, and we would not recommend preparing baby food from them for subsequent freezing of baby puree. It is clear that sometimes parents have no choice and have to start complementary foods with purchased frozen food, so we carefully choose the packaging and the manufacturer, without holes, without pieces of ice.

For example, from frozen vegetables (home-made or a good quality store-bought bag) that were raw when frozen, we cook a roast, we freeze the leftovers of the roast and use it for its intended purpose next time, but it is not worth freezing the roast after the last defrosting.

Why not refreeze

Do not refreeze thawed food, this is a correct statement. Re-freezing a defrosted product can affect the quality and taste (and possibly nutritional value) of the product, and when it is thawed, pathogenic bacteria may begin to multiply. It is always necessary to prepare defrosted food before re-freezing. The preparation of a thawed product then allows it to be re-frozen in a single cycle. Storing a bag of frozen fruits or vegetables makes food preparation a quick and easy solution. You do not need to defrost the whole package, just get the required amount of the product, and leave the rest in the freezer.

The preparation of a thawed product then allows it to be re-frozen in a single cycle. Storing a bag of frozen fruits or vegetables makes food preparation a quick and easy solution. You do not need to defrost the whole package, just get the required amount of the product, and leave the rest in the freezer.

The easiest way to freeze baby puree is to spoon it into an ice mold, cover with plastic wrap so that there is no air access.

Before using the ice molds, they must be thoroughly cleaned with soap and boiled water. Some parents even immerse their ice molds in boiling water for sanitization (Note: Make sure the sanitization is suitable for the molds before use.)

There are many benefits to storing your child's homemade food in an ice mold:

- Each cube is approximately the same size, which allows parents to determine the amount of food the child consumes.

- Minimal waste with only 1 cube at a time and no need to throw away a lot of food.

- Another advantage is that the ice molds are close at hand and you don't have to go out and buy them.

- The time spent in the kitchen is significantly reduced.

You can transfer baby puree cubes to freezer bags, freeing up molds for the next batch of food and also freeing up some freezer space.

Do not forget about the labeling of packages with cubes of baby puree, write the date of freezing and the type of puree. This will help you quickly remove the cube from the package, as well as monitor their expiration date.

Ice crystals on baby food cubes

Don't worry if ice crystals are visible on baby food cubes. It's not frostbite, but excess liquid used in mashing that rises and solidifies at the top of the cubes. These crystals or frost are not dangerous and will not make baby puree cubes inedible or harmful.

Frostbite - what is it and how to determine?

Frostbite looks like greyish brown spots on frozen food. It looks like a leathery type of texture and is easily noticeable. Crystals on frozen foods are not frostbite, but are the result of excess liquid during the freezing process and the formation of ice crystals.

It looks like a leathery type of texture and is easily noticeable. Crystals on frozen foods are not frostbite, but are the result of excess liquid during the freezing process and the formation of ice crystals.

Frostbite does not make frozen foods bad or harmful; it just makes the affected areas very dry. The only thing that can suffer in food that is frostbitten is the quality. You can cut off frostbitten areas and use the undamaged area of food. Frostbite is the result of excess air in a frozen bag that sinks onto food. Eliminate air pockets in bags to help stop frostbite.

Can glass baby food freezer jars or baby food jars like Frutonyanya or Gerber be used

Glass that is not made specifically for freezing has the unfortunate ability to crack, leaving behind tiny, microscopic shards and fragments and also such banks are prone to rupture. Baby food jars are not manufactured for freezing or extreme heating. There are glass jars for freezing food in them, but they can be hard to find. Many people freeze in baby food jars, but I'm not a fan of this at all. After all, food is made for the baby because we want to give him the best healthy food; Do you really want to take the risk and freeze baby food in glass jars?

Many people freeze in baby food jars, but I'm not a fan of this at all. After all, food is made for the baby because we want to give him the best healthy food; Do you really want to take the risk and freeze baby food in glass jars?

There are certain plastic jars that are specially made to withstand high temperatures and/or freezing. Therefore, it is best to use plastic containers or ordinary thick plastic bags, convenient and simple. There are also special freezer bags with a zip clip - an interesting option.

Can previously frozen breast milk or formula be used to make vegetable or fruit purees?

Do not use previously frozen breast milk to prepare puree to freeze this baby food later.

Breast milk should never be re-frozen in any shape or form.

Milk formula

You can freeze puree to which defrosted milk formula has been added. However, formula should not be frozen in bottles or cans. It is impossible to add the mixture to the previously frozen mixture and freeze it. If frozen milk formula is used for mashing, then it is necessary to freeze it at a time without defrosting. Freezing milk formula causes separation of fats and liquids, and the texture suffers accordingly. Although there is no health risk, the same happens with breast milk and cow's milk, the texture and quality suffer a little. However, it is best to prepare the milk formula before putting it in the baby puree and only then freeze the puree. This will be more useful and efficient.

It is impossible to add the mixture to the previously frozen mixture and freeze it. If frozen milk formula is used for mashing, then it is necessary to freeze it at a time without defrosting. Freezing milk formula causes separation of fats and liquids, and the texture suffers accordingly. Although there is no health risk, the same happens with breast milk and cow's milk, the texture and quality suffer a little. However, it is best to prepare the milk formula before putting it in the baby puree and only then freeze the puree. This will be more useful and efficient.

Some formula manufacturers say that freezing any formula is not recommended, as the process can alter physical properties such as fat separation, which can be difficult for sensitive babies to digest. Freezing does not affect the quality or food sterility, however it will not prolong the shelf life of formula. Freezing may result in the loss of the desired appearance and functionality and is therefore not recommended.

.jpg)