Combi baby food cutter

Snoopy Peanuts Baby Food Scissors/ Baby Food Cutter with Cover (Blue/ Pink) Stainless Steel

9

20

9

20

9

20

9

20

9

20

9

20

9

20

9

20

- Product

- Description

- Reviews (0)

- What's in the box

Description

Highlight

- Stainless steel blades, hard, and excellent anti-erosion properties

- Safety button, safety to use, and reduce the risk of baby misusing

- Ergonomically grips-arc curved specially designed, easy to use

- Perfect size when on the go

- Come with a hygienic cap, keep blades clean and hygienic when on the go

- Can be used as general scissors

FEATURES

- Stainless steel blades, hard, and excellent anti-erosion properties

- Safety button, safety to use, and reduce the risk of baby misusing

- Ergonomically grips-arc curved specially designed, easy to use

- Perfect size when on the go

- Come with a hygienic cap, keep blades clean and hygienic when on the go

- Can be used as general scissors

Size:15. 5cm x 7cm

Reviews (0)

view all

back

0 reviews

What's in the box

1 x Snoopy Peanuts Baby Food Safety Scissors with Cover

BestsellersMore

LatestMore

Favourite Brands

Combi Baby label baby food navigate cooking set C - Japanese Product Online Store

out of stock Add to wish list

What's SaQraMart

Our goal is to provide the world with safe, reliable and high quality Japanese products...

- Combi(5)

- Review(0)

$40.98

1 %point addedItem #: 4972990148436

Quantity: No Stock

* It may differ from the actual stock quantity.

ATTENTION: Each country has its own list of prohibited items. Please check whether or not the item is a prohibited item in your region prior to finalizing your purchase.

●Delivery: Available Delivery Area / methods

check >

Due to the current COVID-19 pandemic.

Japan Post has suspended delivery to many countries.

【Available Delivery methods / Area】Last updated: November 15, 2022(JST)

| Country | DHL | EMS | ePacket | UPS |

|---|---|---|---|---|

| Australia | ✓ | ✓ | ||

| Bangladesh (second zone) | ✓ | ✓ | ||

| Bhutan (second zone) | ✓ | ✓ | ||

| Germany | ✓ | |||

| Hong Kong | ✓ | ✓ | ||

| Korea | ✓ | ✓ | ||

| Macao (second zone) | ✓ | ✓ | ||

| Malaysia (second zone) | ✓ | ✓ | ||

| Netherlands | ✓ | ✓ | ||

| New Zealand | ✓ | |||

| Philippines | ✓ | ✓ | ||

| Singapore | ✓ | ✓ | ||

| Taiwan | ✓ | ✓ | ||

| Thailand | ✓ | ✓ | ||

| United Kingdom | ✓ | |||

| United States of America | ✓ | |||

| Vietnam | ✓ | ✓ |

(Country names are in alphabetical order. )

)

Other countries

Please note that orders made from other countries will automatically be rejected.

We ask for your understanding during these uncertain times.

read more

The following estimated delivery periods mean the delivery time after the shipping status is changed to "shipped".

・Epacket - Express Mail (Estimated Shipping Time 7-20 days)

・EMS - Express Mail (Estimated Shipping Time 3-6 days)

・DHL (Estimated Shipping Time 3-6 days)

*If backordered item is included in your order,it will be shipped after all the items are prepared.

●Payment

●Returns

・No cancellation caused by customers would be accepted

・The posted image may differ from the actual product package. We can not accept returns/exchanges due to package differences. > see details

●Notice

・The description of the product package etc is all in Japanese.

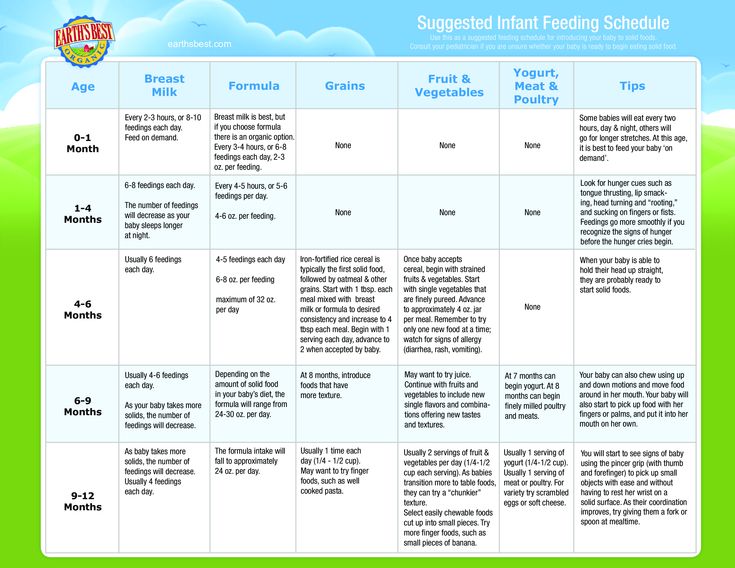

A cooker set that navigates from baby food to its completion!

Make baby foods that match your baby's growth, such as mashing, boiled, heating & thawing, cutting corners, grated, and scouring the back!

Includes a collection of baby food recipes.

Contains mortar bowl, ground bowl, back plate, grater plate, cut plate, range lid and spatula.

Compatible with dishwashers and microwave ovens. (* The back plate and cut plate do not support microwave ovens.)

<Set contents>

ground bowl

A bowl with protrusions that makes it easy to grind ingredients. Combined with the lid for the range, it can be boiled and boiled, and cooked or warmed for thawing.

Cut plate

A plate that can be easily cut into 5mm square or 10mm square simply by placing boiled vegetables and pressing with a spatula.

Range lid

A convenient lid for cooking and warming.

Grated plate

A plate that can be used to finely squeeze vegetables and fruits. You can choose the roughness of the front and back.

You can choose the roughness of the front and back.

Back plate

A plate that can be used to paste boiled vegetables and porridge in a paste.

mortar bowl

There is an uneven groove to grind ingredients finely. Combined with the lid for the range, it can be boiled and boiled, and cooked or warmed for thawing.

Spatula

Easy to use and easy to use.

Set content

Mortar bowl, ground bowl, back plate, grater plate, cut plate, lid for range, spatula

Specification

mortar bowl

Raw material resin: Polypropylene

Heat-resistant temperature ... 140 degrees

Cold resistance temperature -40 degrees

Capacity ... 330mL

Microwave oven ...

ground bowl

Raw material resin: Polypropylene

Heat-resistant temperature ... 140 degrees

Cold resistance temperature -40 degrees

Capacity: 280mL

Microwave oven ...

Back plate

Raw material resin: Frame: ABS resin, strainer: Stainless steel

Heat-resistant temperature . .. 100 degrees

.. 100 degrees

Microwave oven ××

Grated plate

Raw material resin: Polypropylene

Heat-resistant temperature ... 140 degrees

Cut plate

Raw material resin: Frame: ABS resin, Cut part: Stainless steel

Heat-resistant temperature ... 100 degrees

Microwave oven ××

Range lid

Raw material resin: Polypropylene

Heat-resistant temperature ... 140 degrees

Cold resistance temperature -40 degrees

Microwave oven ...

Spatula

Raw material resin: Polypropylene

Heat-resistant temperature ... 140 degrees

Note

Be sure to read the instruction manual carefully before using the product. Please keep it carefully after reading.

No review on this item...

Design and principle of operation of a plasma cutter

Plasma torch - the basic element of a plasma cutting machine

Plasma cutting has long established itself as a high-performance, safe and high-speed metal processing method that allows you to get a clean and even surface without additional processing. The main "participant" of this process is the cutter - the basic working body of the plasma cutter. Despite the growing interest in the technology, confusion in terminology still remains: sometimes the “plasma torch” is mistakenly taken to mean the entire cutting installation. What is this device and how exactly is it arranged?

The main "participant" of this process is the cutter - the basic working body of the plasma cutter. Despite the growing interest in the technology, confusion in terminology still remains: sometimes the “plasma torch” is mistakenly taken to mean the entire cutting installation. What is this device and how exactly is it arranged?

Plasma torch components

- Plasma jet nozzle. The size of the cut, the characteristics of the arc and the cooling rate of the equipment largely depend on the diameter of the component and its length: the longer it is, the more accurate the cut is, but at the same time the service life is reduced.

Pure copper nozzles are considered to be the best, as this material successfully combines high thermal conductivity and low cost.

- Electrode holder with a cathode (electrode) made most often from hafnium, less often from zirconium, beryllium or thorium (oxides of the latter can be toxic or radioactive and harm the health of the operator, so they are not used so often).

- Arc chamber for air flow.

- Insulating sleeve separating the electrode and nozzle assemblies.

- Casing on the outside.

- Cable-hose package that connects the device to the power supply. The cable is used to transfer current from the inverter or transformer, and the hose is used to transport compressed air.

- Roller stops, cutter head, protective cap are also included in the design of the device, although they are not directly involved in the process.

The package may also include a swirler, for example made in the form of ceramic rings or washers. Placed in front of the entrance to the nozzle assembly, such devices provide a vortex supply of gas to the arc chamber and contribute to more efficient compression of the arc and its stabilization.

When processing metal up to 10 mm thick, one set of "nozzle + electrode" is enough for about 8 working hours

Principle of operation high-frequency currents enter the plasma torch.

Under their influence, a standby electric arc with a temperature of 6000 - 8000 ° C is formed inside the apparatus between the nozzle tip and the electrode, the column of which fills the entire channel.

Under their influence, a standby electric arc with a temperature of 6000 - 8000 ° C is formed inside the apparatus between the nozzle tip and the electrode, the column of which fills the entire channel. Compressed air enters the chamber through a hose. Passing through the electric arc, it heats up and ionizes, acquiring conductive properties, and the volume increases by 50-100 times. The nozzle, narrowed down, forms an air stream that is ready to break out at high speed. It is this ionized air heated to 25000-30000 ° C that is called the plasma that makes the cut.

Plasma-forming gases are oxygen, a mixture of hydrogen with argon, nitrogen. In industry, in addition to them, a number of protective gases (helium, argon) and their mixtures are used.

At the moment when the plasma comes into contact with the metal surface, the pilot arc goes out, and the working or cutting one lights up instead. Under its action, the metal melts, forming a cut, and the molten particles are removed by a high-pressure jet.

Plasma torches are cooled by air or water. The first option with the use of gas flows is relevant for low-power installations. The second - with circulating water - is practiced in high-power devices in large-scale production. The "liquid" technology is more efficient, but it makes the design of the device heavier and increases the cost of its operation.

Using this uncomplicated-looking device allows not only making straight cuts, but also making curved cuts, openings and holes, leveling edges, etc. – both in small workshops and on an industrial scale.

How to choose a professional cutter - advice from KLEN

- home

→ -

How to choose

→ -

How to choose a professional cutter

Wiping and cutting machines - industrial technological equipment for:

- Cutting into sticks, cubes, slices, slices, straws of various sizes of raw and boiled vegetables and fruits

- High-quality crushing of crackers, cheese

- Preparation of fruit and berry jams, sauces and mashed potatoes, cucumbers, legumes, carrots, tomatoes, cottage cheese, cereals.

Wiping and cutting machines are installed at vegetable and fruit processing plants, kitchen factories, salad shops, canteens, cafes, restaurants, fast food outlets for preparing salads, side dishes and desserts.

Main components:

- Robust metal housing with corrosion protection

- Plastic cooking chamber with lid

- Food containers

- Powerful motor with thermal protection

- Keypad

- Shredders - sharp knives and discs

- Inclined surface for the exit of processed products

The principle of operation is as follows. Vegetables and fruits are pre-washed, cleaned and loaded into a receiving hopper. The feed of products to the cutting discs is provided by a pusher. The processed raw material at the exit is sent to a substituted container.

The equipment is connected to a 380 V network and is operated at temperatures from +1 °С to +40 °С. The overall dimensions of the cutting and wiping machines - 600x340x650 mm allow you to install compact equipment in a professional kitchen with a limited area.

Before working with a professional machine for cutting and mashing food, personnel should read the instructions and operating rules. For the safety of employees, work is blocked if the lid is opened and foreign objects get into the bowl.

Features of professional equipment for chopping products

The catalog of the online store KlenMarket.ru presents equipment for cutting and rubbing fruit and vegetable products of the Belarusian manufacturer Torgtekhmash. According to their functional characteristics, the models are divided into the following types:

- For chopping raw, blanched and boiled vegetables and fruits. The MPR-350M-02 machine processes at least 350 kg/h. The set includes knives: for fine grinding, disk grater, combined, knife for shredding and disk. Recommended for preparing appetizers, salads and side dishes in catering establishments for 150-250 seats.

- For pureeing products that have undergone heat treatment - fruits, berries and vegetables, curd mass, liquid cereals.

Model MPR-350M-01 with two interchangeable discs wipes boiled potatoes, zucchini, cauliflower, beets, carrots, apples up to 600 kg/h. Suitable for confectionery factories, baby food factories and other food industries.

Model MPR-350M-01 with two interchangeable discs wipes boiled potatoes, zucchini, cauliflower, beets, carrots, apples up to 600 kg/h. Suitable for confectionery factories, baby food factories and other food industries. - Combined wiping-cutting machine MPR-350.00M is used for grinding raw and boiled fruits and vegetables and rubbing boiled products. Productivity — 350/600 kg/h. The set includes several interchangeable knives and discs for wiping with holes of different diameters. It is used in food production, catering establishments, hotels serving 1500-2000 visitors per day.

Benefits of using cutters:

- Quick and high-quality chopping and mashing of vegetables, fruits, cereals

- Quality separation of skins, seeds and minimum waste

- Pureed product has a uniform composition

- Energy saving

How to choose a cutting and cutting machine

0003

- Equipment capacity - models shown handle 100 to 600 kg/h

- Mounting Method - Floor and Table Models

- Complete set - a set of wiping nozzles, knives and discs for curly cutting products of different degrees of readiness

- Voltage - industrial equipment is connected to the mains 380 V

Choose the right machine for your business.